Maintaining the tyre balance on your vehicle is critical to receiving satisfactory service from your tyre investment. In addition to providing a smooth ride, balancing is a key component in tyre wear. The focus of this article is to help you understand the balancing process and to know why it is important to keep your tyres balanced throughout their tread life.

For those of you who may think that tyre balancing isn’t that important, consider some industry trends—they may help you rethink the issue. Perhaps the most compelling argument for precision balancing comes from an obvious fact… vehicles are being made lighter and lighter. The heavier cars of yesterday actually helped smooth-out the ride by damping many vibrations before they could be felt by the driver. The softer suspensions also had the same effect. The second factor is tyre technology; generally, more responsive tyres with lower profiles (which send more road feedback to the driver) are being used in today’s style and performance oriented market. By the way, lower profile tyres do provide lower rolling resistance, which helps fuel economy. As a result, the slightest imbalance (as little as half an ounce) can be felt in most modern vehicles; this is significantly less than the average of ten years ago. For those of you who have plus-sized your tyres and wheels, balancing is even more critical.

The balancing act

Perhaps the best way to begin is to discuss the lack of balance. When a tyre is mounted onto the wheel, two slightly imperfect units are joined to form an assembly weighing forty pounds (this is the average for cars). The chances of this assembly having absolutely precise weight distribution about its radial and lateral centers are virtually impossible. Remember that all it takes is half an ounce of uneven weight distribution for a vibration to be felt.

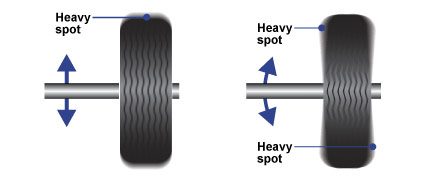

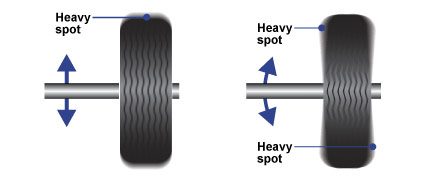

Left: Static imbalance Right: Dynamic imbalance

Static imbalance:

Occurs when there is a heavy or light spot in the tyre so that the tyre won’t roll evenly and the tyre and wheel undergoes an up-and-down motion.

Dynamic imbalance:

Occurs when there is unequal weight on one or both sides of the tyre/wheel assembly’s lateral center-line, thus creating a side-to-side wobble or wheel shimmy.

The static imbalance creates a hop or vertical vibration. The dynamic imbalance creates a side-to-side or wobbling vibration. Most assemblies have both types of imbalance, and require dynamic balancing (commonly referred to as spin balancing) to create even weight distribution. The balancing system directs a technician to place counter weights on the rim’s outer surface to offset the imbalance. When the balancing system tests for virtually perfect weight distribution, the assembly is in balance and will not vibrate. Your tyres will ride smoothly and wear evenly (with regard to balance).

Keeping your tyres balanced

For sake of example, assume you have driven your tyres 5,000 kilometres since their purchase and it’s time to rotate. Over the miles, turning left and right, hitting bumps and holes you could not see or avoid, and driving down uneven road surfaces have led to uneven treadwear on your tyres. Perhaps a pothole has knocked-out your vehicle’s alignment (this creates uneven tyre wear). Well, besides rotating the tyres and getting an alignment to set things right, you should also rebalance the tyres. Even if you can’t feel vibrations, they are present. The uneven treadwear has created an imbalance that generates excessive heat and wear on your tyres! Considering the hundreds of dollars you spent on your tyres, a rebalance is a wise expenditure.

Other sources of vibration

Very often the wheel/tyre assemblies on a vehicle may be in balance but you still feel a vibration. Here are some of the other causes of vibration:

- Bent wheel

- Tyre out of round (radial or lateral runout)

- Wheel to axle mounting error

- Inconsistent tyre sidewall stiffness (force variation)

- Brake component wear or failure

- Drive train or engine component wear or failure

- Suspension wear or failure

- Wheel bearing wear of failure

- Wheel alignment is out

Your tyre dealer can isolate many of these problems for you, and there is no question that determining whether the tyre/wheel assemblies are good and in balance is the first place to start. But ultimately this may not be the source of your vibration problem.

Balancing high performance tyres and wheels

Match Mounting

Today’s high performance tyres and wheels are made with features that facilitate optimum mounting. Wheels are marked to identify the minimum radial run-out spot (low point) on the bead seat surface. Tyres are marked with a high point location. Mounting the assembly to match these two points is called match mounting. This method minimizes the balance weight needed to correct any remaining imbalance and the radial run-out that may occur in the wheel/tyre assembly.

Force Variance

On rare occasion, a tyre may be manufactured with slightly inconsistent sidewall stiffness (creating what is called force variance) which leads to a ride problem. There is a new generation of balancers that can detect this condition and guide the technician to remount the tyre in an optimum position that puts the assembly within specification and eliminates the problem.

Wheel Weight Placement

Many of today’s wheel designs necessitate unique wheel weight placement to achieve both precise balance and aesthetic appeal. Your tyre dealer will inform you of the best method for your wheel type.

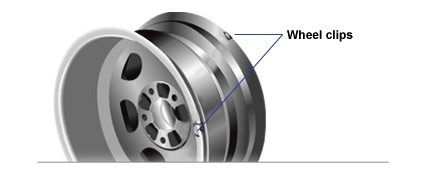

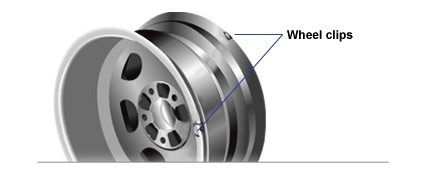

Standard balance uses only clip-on weights as shown. This method is usually done on original equipment steel or alloy wheels (different type wheel weights are used for each type of wheel).

Left:

Left: Mixed weights balance uses both clip-on and adhesive weights. The balance planes maintain the weights behind the face of the wheel.

Right: Adhesive weights balance uses only adhesive weights, typically for chrome or other wheels with a delicate finish. The balance planes maintain the weights behind the face of the wheel.

Left: Mixed weights balance uses both clip-on and adhesive weights. The balance planes maintain the weights behind the face of the wheel.

Right: Adhesive weights balance uses only adhesive weights, typically for chrome or other wheels with a delicate finish. The balance planes maintain the weights behind the face of the wheel.

Left: Mixed weights balance uses both clip-on and adhesive weights. The balance planes maintain the weights behind the face of the wheel.

Right: Adhesive weights balance uses only adhesive weights, typically for chrome or other wheels with a delicate finish. The balance planes maintain the weights behind the face of the wheel.